Monitor

Display Application

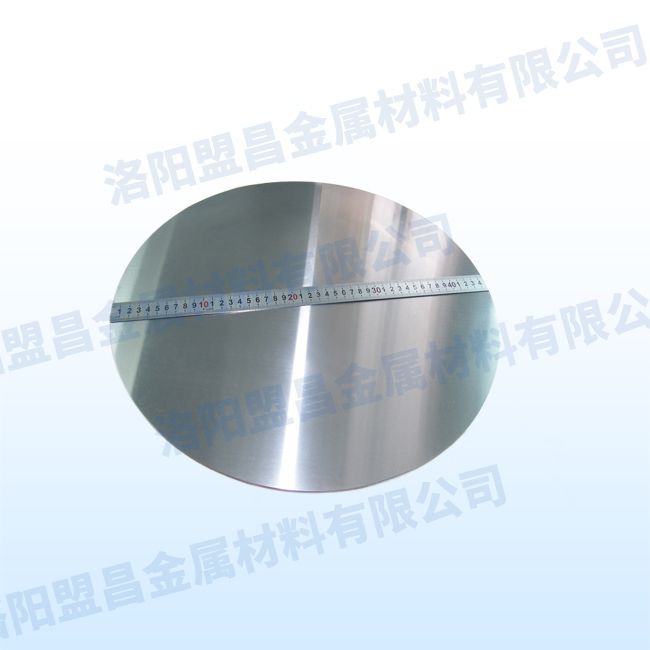

With the rapid progress of modern technology, monitors, as a window for media communication, are widely used in various industries. It is very important to stably ensure the current display quality and the improvement of future display quality, which corresponds to the quality of raw materials for display production. , and the important link of tungsten and molybdenum target sputtering coating on the display, the purity, density of raw materials, and the compactness of the internal structure are the key factors. It can be guaranteed that the various characteristics of the sputtering target meet the high-level display requirements of modern production.

Sputtering technology is one of the main technologies for the preparation of thin film materials. It uses ions generated by ion sources to accelerate and aggregate in vacuum to form high-speed energy ion beams, bombard the solid surface, and exchange kinetic energy between ions and solid surface atoms. , so that the atoms on the surface of the solid leave the solid and deposit on the surface of the substrate. The bombarded solid is the raw material for depositing thin films by sputtering, which is called the sputtering target. Various types of sputtered thin film materials have been widely used in semiconductor integrated circuits, recording media, flat-panel displays and workpiece surface coatings.

Sputtering Target Application:

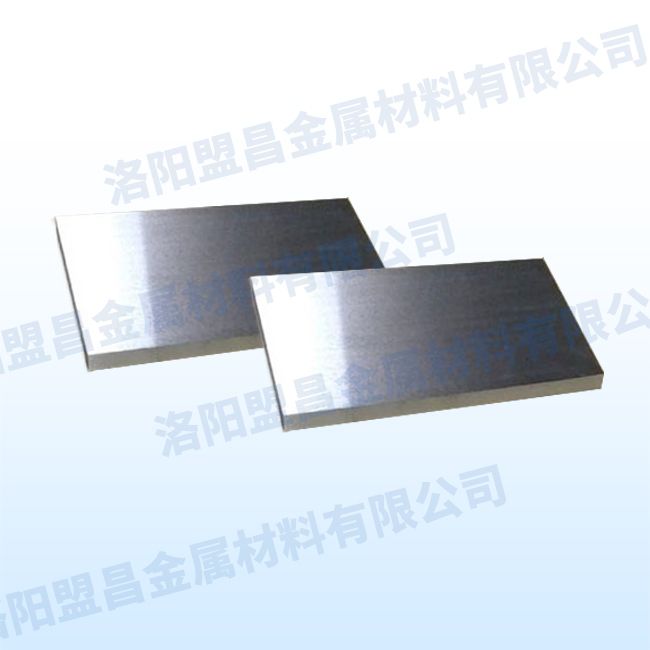

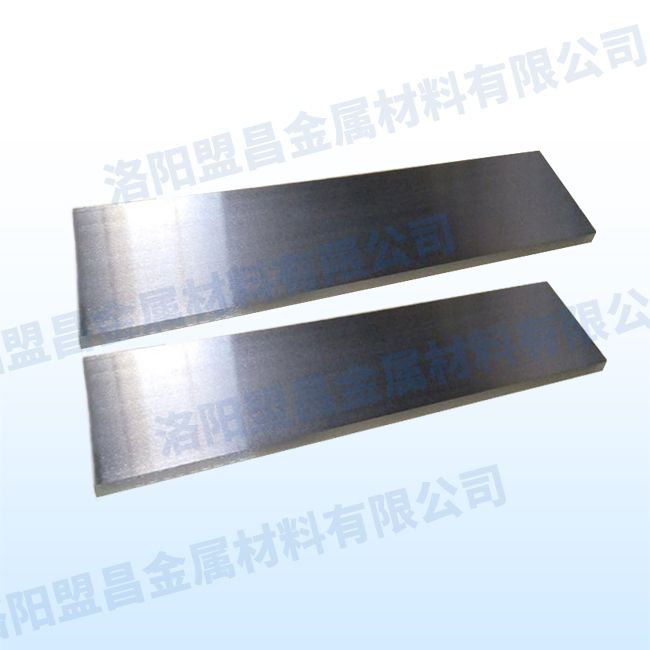

Sputtering targets are mainly used in the electronics and information industries, such as integrated circuits, information storage, liquid crystal displays, laser memories, electronic control devices, etc.; they can also be used in the field of glass coating; they can also be used in wear-resistant materials, high-temperature corrosion resistance , high-end decorative products and other industries.

As one of the three processes of vacuum coating, sputtering coating is widely used in modern industries such as photovoltaic and TFT-LCD. Sputtering targets have high requirements for purity. Generally, tungsten and molybdenum sputtering targets require a purity of more than 99.95%, and have good density and corrosion resistance.

Craftsmanship

TEL

TEL skype

skype Message

Message