Solar Photovoltaic Industry

Tungsten and Molybdenum Modules for Solar Photovoltaic Industry

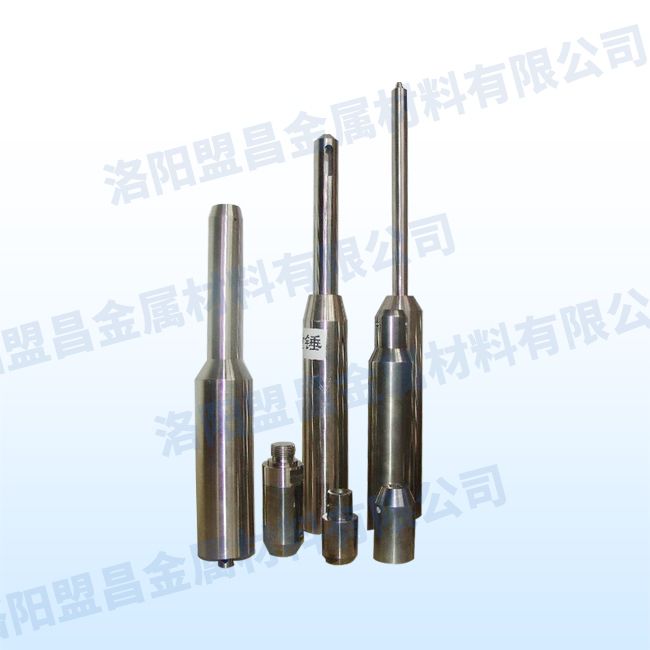

Monocrystalline silicon, a large number of raw materials required by the semiconductor and photovoltaic industries, is prepared and produced by the special equipment "monocrystalline silicon crystal growth furnace". Increasing the capacity of monocrystalline silicon and reducing the production cost of monocrystalline silicon have long been the technical topics that crystal manufacturers have to solve through equipment improvement and optimization. Increasing the crystal drawing speed is one of the important means to effectively improve the production efficiency and control the production cost.

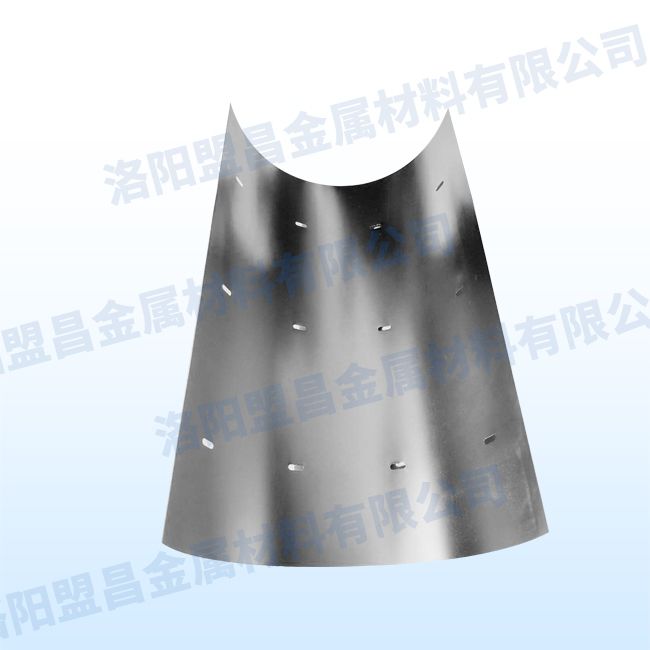

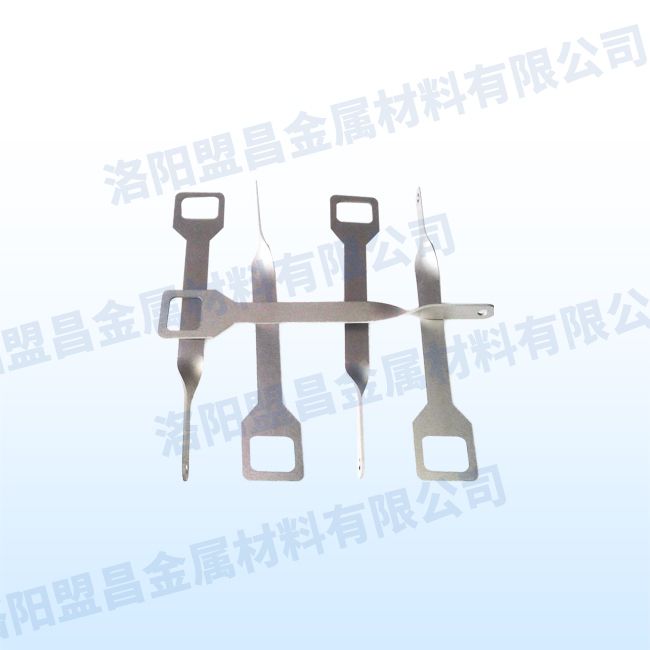

In recent years, crystal manufacturers at home and abroad have added a layer of molybdenum draft tube (also called draft tube molybdenum bushing) in the graphite draft tube. The application of this technology and product not only isolates the direct radiation of graphite and crystal rods, effectively control the temperature of the ingot, and further improve the pulling speed. At present, all kinds of furnace-type molybdenum draft tubes for the production of single crystal silicon draft tubes. And the flat draft tube and wave linear draft plate selected in the crystal pulling market can only solve the problem of preventing light and heat radiation. The temperature center of the ingot is too high, which seriously affects the crystal pulling speed problem, and at the same time, the lifespan is also low, resulting in high manufacturing cost of single crystal silicon.

Craftsmanship

TEL

TEL skype

skype Message

Message