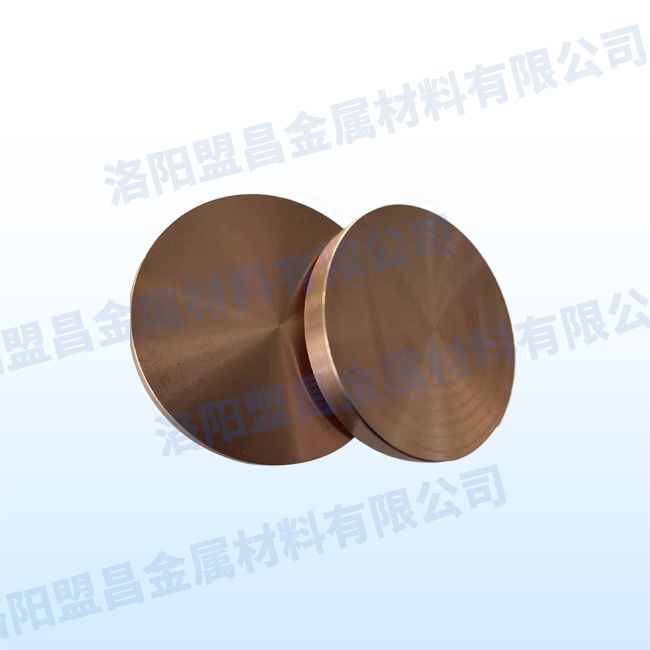

WCu Alloy

Material Properties

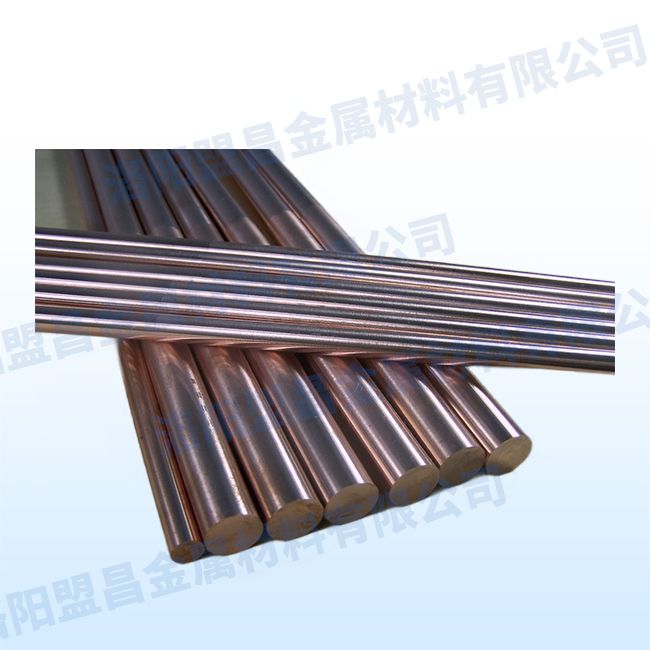

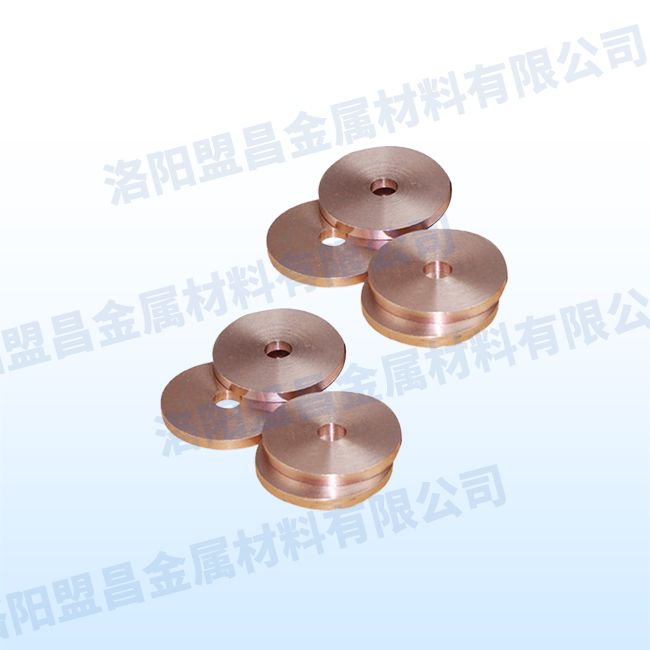

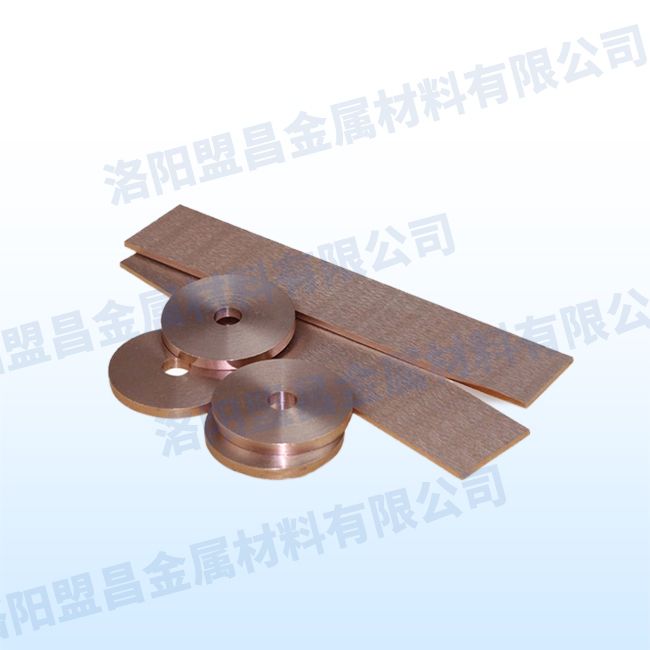

WCu Alloy combines the advantages of tungsten and copper. Among them, tungsten has high melting point (tungsten melting point is 3420 ℃, copper melting point is 1080 ℃) and high density (tungsten density is 19.3g/cm, copper density is 8.89/cm3); Copper has excellent conductivity and thermal conductivity, and tungsten copper alloy (composition generally ranges from wcu7 to wcu50) has uniform microstructure, high temperature resistance, high strength, arc erosion resistance and high density; With moderate conductivity and thermal conductivity, it is widely used in high-temperature resistant materials, electrical alloys for high-voltage switches, EDM electrodes, and Microelectronic Materials. As parts and components, it is widely used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment and other industries.Craftsmanship

Product Specifications

| Type | Chemical Composition(weight %) | Density | Solidity | Resistivity | Conductivity | Bending strength | ||

| Cu | Total Impurities≤ | W | g/cm3 ≥ | Brudzinski HB Kgf/mm2 ≥ | μΩ.cm ≤ | % ≥ | MPa ≥ | |

| WCu50 | 50±2.0 | 0.5 | margin | 11.85 | 115 | 3.2 | 54 | -- |

| WCu45 | 45±2.0 | 0.5 | margin | 12.3 | 125 | 3.5 | 49 | -- |

| WCu40 | 40±2.0 | 0.5 | margin | 12.75 | 140 | 3.7 | 47 | -- |

| WCu35 | 35±2.0 | 0.5 | margin | 13.3 | 155 | 3.9 | 44 | -- |

| WCu30 | 30±2.0 | 0.5 | margin | 13.8 | 175 | 4.1 | 42 | 790 |

| WCu25 | 25±2.0 | 0.5 | margin | 14.5 | 195 | 4.5 | 38 | 885 |

| WCu20 | 20±2.0 | 0.5 | margin | 15.15 | 220 | 5 | 34 | 980 |

| WCu15 | 15±2.0 | 0.5 | margin | 15.9 | 240 | 5.7 | 30 | 1080 |

| WCu10 | 10±2.0 | 0.5 | margin | 16.75 | 260 | 6.5 | 27 | 1160 |

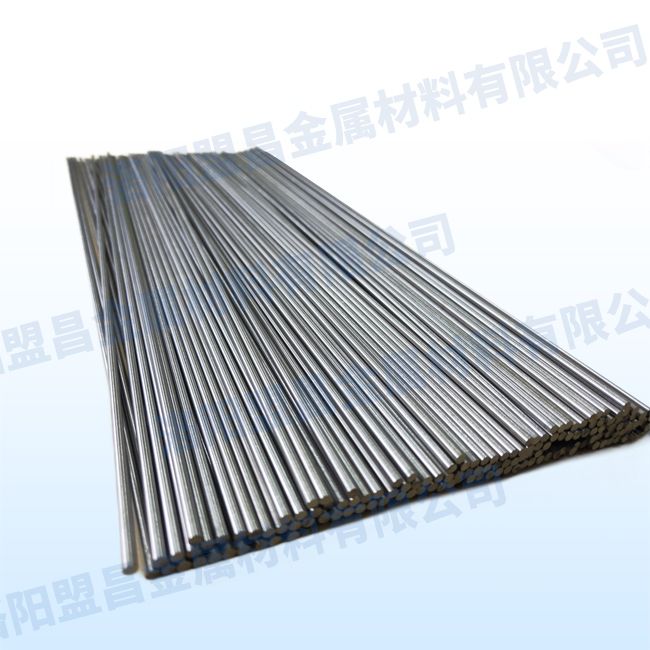

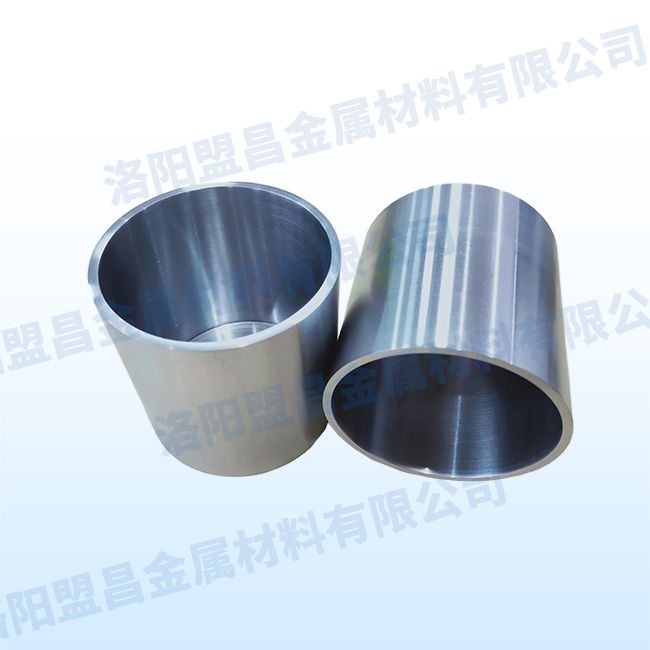

Other Products

TEL

TEL skype

skype Message

Message