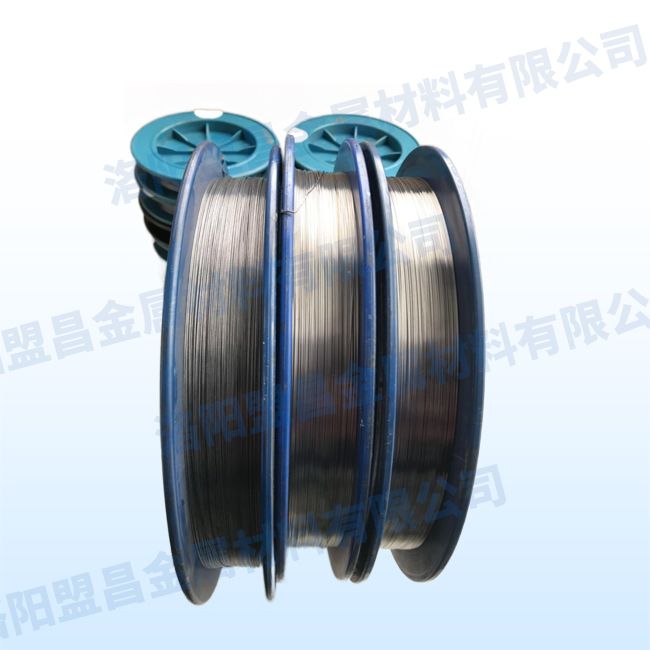

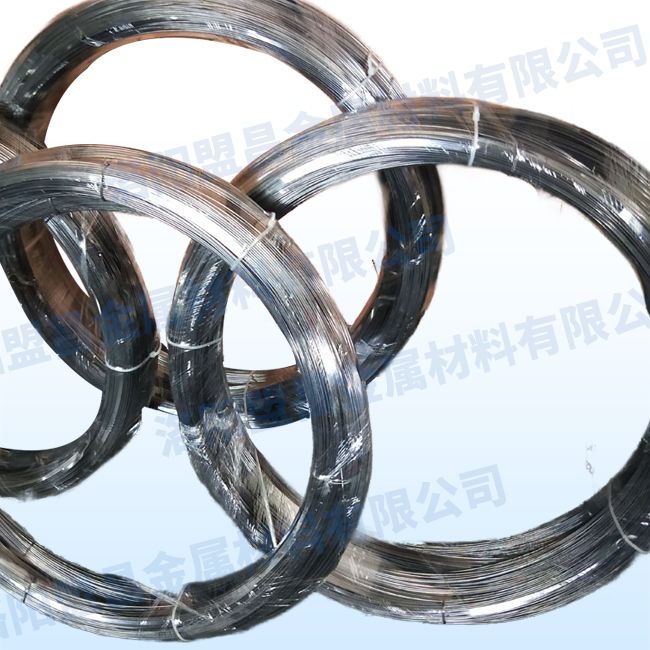

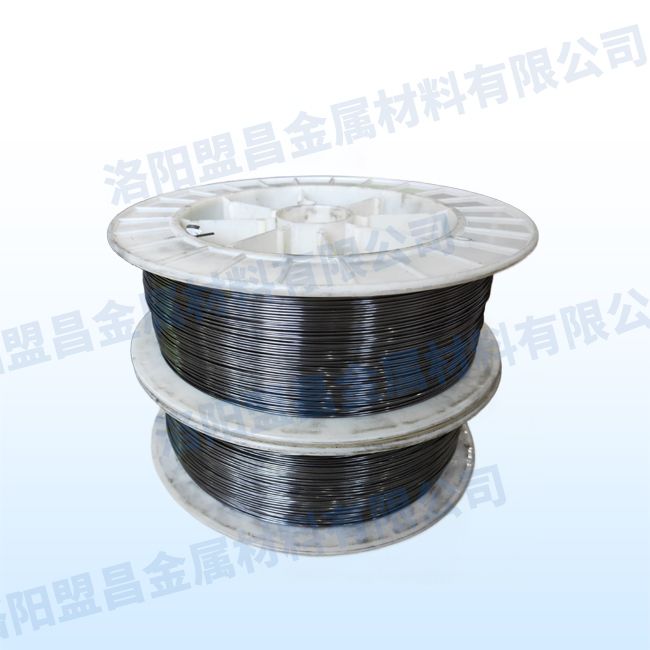

Molybdenum wire

Material Properties

Molybdenum, located in period 5, has a melting point of 2610ºC, a boiling point of 5560°C and a density of 10.2g/cm³, which is insoluble in water. With an atomic radius of 139pm and an electronegativity of 2.16, molybdenum is low expansion coefficient, high strength at high temperature (1100 ~ 1650 ℃) which is easy to process compared with tungsten. Therefore, it is often used in high temperature furnace, electron tube, electric light source, metal processing tool manufacturing sector and aerospace industry. Molybdenum is resistant to corrosion by molten glass, and its oxides do not contaminate the glass. Molybdenum has been used in the glass industry as heating electrodes and as sputtered palladium for solar cell and flat panel display coatings.Craftsmanship

Chemical Composition

| Molybdenum content | Total content of other elements | Content of each element |

| ≥99.97% | ≤0.03% | ≤0.01% |

Product Specifications

| Nominal diameter(μm) | 200mm wire weight(mg/200mm) | 200mm wire segment weight tolerance(%)(mg/200mm) | Diameter tolerance( %) | ||

| GradeⅠ | Grade Ⅱ | Grade Ⅰ | Grade Ⅱ | ||

| 20≤d<30 | 0.65-1.47 | ±2.5 | ±3 | ||

| 30≤d<40 | >1.47-2.61 | ±2.0 | ±3 | ||

| 40≤d<100 | >2.61-16.33 | ±1.5 | ±3 | ||

| 100≤d<400 | >16.33-256.2 | ±1.5 | ±4 | ||

| 400≤d<600 | ±1.5 | ±2.5 | |||

| 600≤d<3200 | ±1.0 | ±2.0 | |||

Applications

-Used as cutting wire.

-Used as making electric light sources and electric vacuum parts.

-Used as high temperature heating element and high temperature structural parts.

-Used for high temperature spraying to improve the wear resistance of automobiles and other mechanical parts.

Other Products

TEL

TEL skype

skype Message

Message