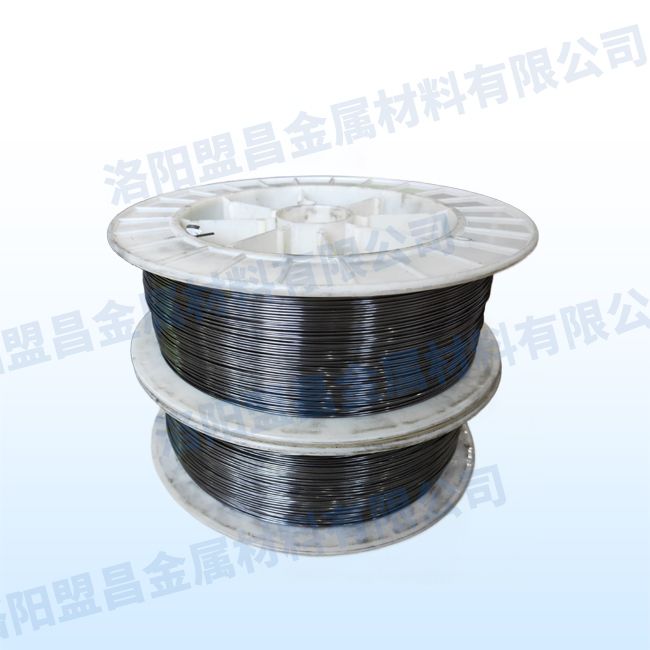

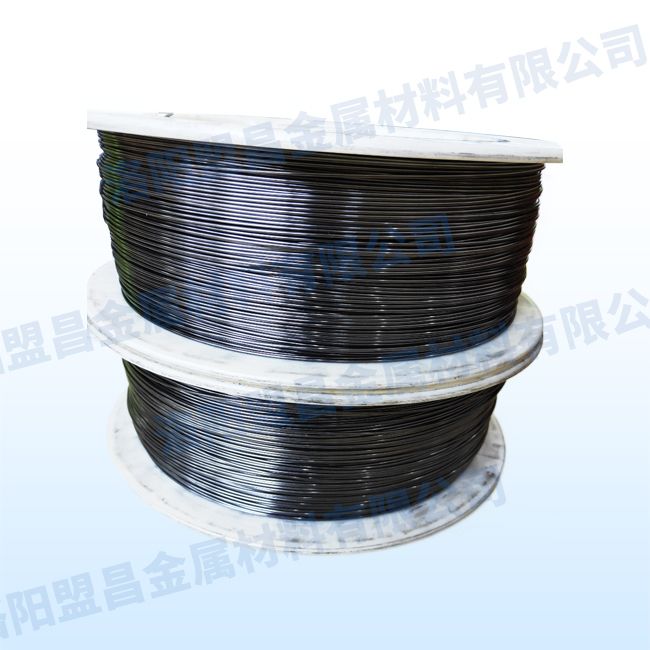

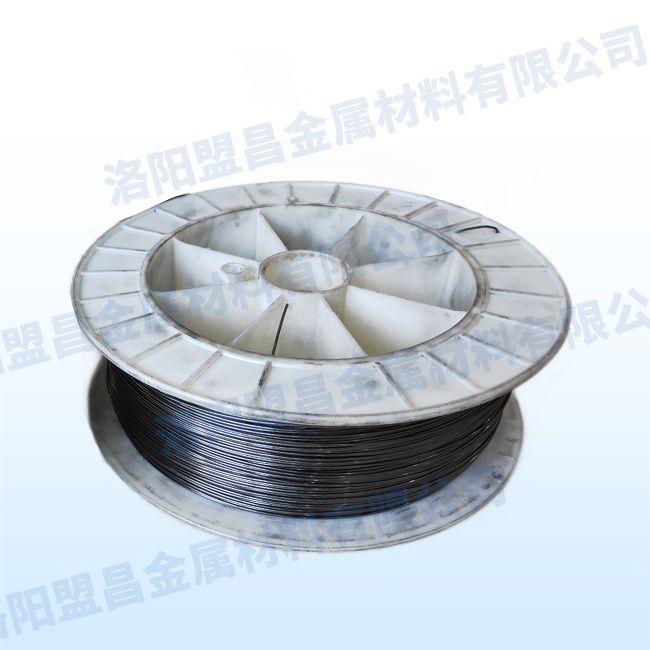

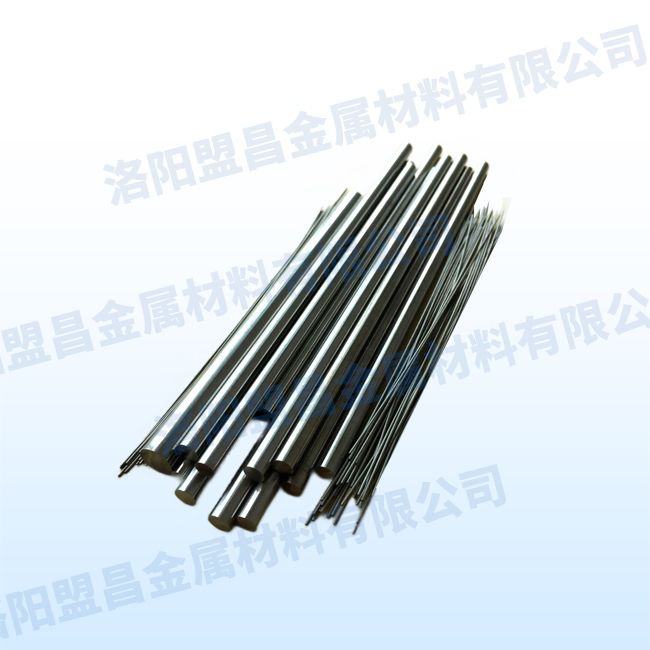

Spraying molybdenum wire

Material Properties

Molybdenum wire has high wear resistance, which has become an indispensable metal spray material. Thin-layer spraying of molybdenum wire can be used to manufacture automotive mechanical parts (such as piston rings, synchro rings, shifting elements) to improve the wear resistance of their surfaces. Spray molybdenum wire is used for automotive parts that suffer from wear, such as piston rings, gearbox synchronizer parts, select fork mechanical parts, such as maintenance purposes. For example, the bearing is sprayed with molybdenum wire, whose surface coating is the bearing shell and shaft. Due to the lack of adhesion of the steel layer, it has no intermediate molybdenum layer .Craftsmanship

Chemical Composition

| Molybdenum content | The total content of other elements | Content of each element |

| 99.95% | ≤0.05% | ≤0.01% |

Product Specifications

| Diameter | Diameter deviation | Tensile Strength | Delivery Instructions |

| 1.41~2.0 | + / -0. 02mm | >700-900N /mm² | The surface is black, the single weight can be up to more than 25 kg, without welding joints. |

| 2.01~3.0 | + / -0. 02mm | ||

| 3.17mm | + / -0. 025mm |

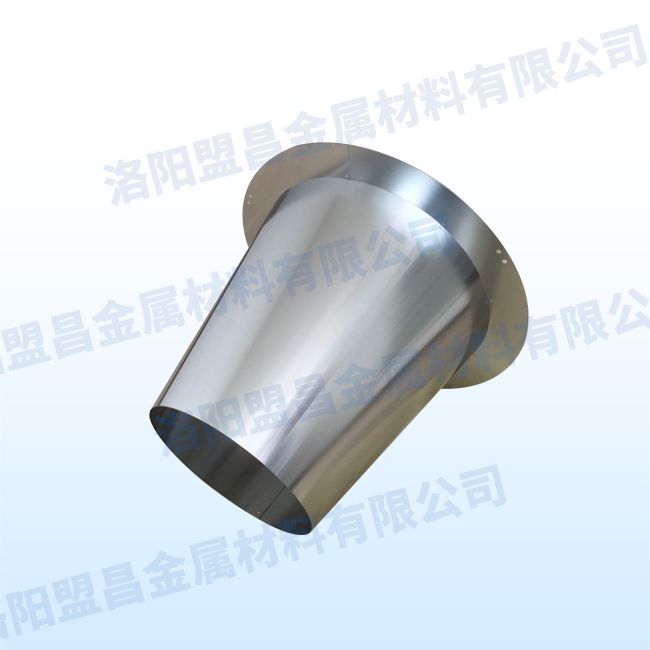

Applications

Spray molybdenum wire is mainly used for fine spraying on the surface of automobile wear parts and mechanical wear surface to enhance the wear resistance.

Other Products

TEL

TEL skype

skype Message

Message